What is post-printing and what is it for?

What is post-printing for?

When the products have already been printed and, in fact, are ready for use, it is the turn of post-printing. This is not an obligatory stage, but the finished appearance, durability, and attractiveness of the printing industry depend on it. Postprinting is conventionally divided into functional and decorative. Let’s take a closer look at each of the categories and the features of its manufacture.

Types of printed materials finishing

Most of the printing industry after printing requires the use of some kind of functional post-printing processing. It can be die-cutting or cutting, creasing, folding, stitching, binding, lacing. At the request of the client, decorative finishing can also be used – foiling, embossing, lamination, perforation, rounding of corners.

- Nibbling, cutting – the process of obtaining the required size of printing. Used to make small items such as postcards, business cards, invitations, etc. Cutting creates simple geometric shapes, and nibbling creates complex shapes.

- Creasing and folding – finishing required to create even and neat folds on booklets, packaging, calendars, folders. Creasing is relevant for products made of thick cardboard, paper, and folding is used for thin printed products.

- Binding – binding of printed pages in different ways – glue, spring, on staples. This is how books, magazines, booklets, catalogs, brochures and other multi-page publications are produced.

- Binding is the step after binding. Arranges individual bound pages into a single piece. It can be hard and soft. The first one is used for books, scientific papers, is more durable, reliable, practical. The second is inherent in magazines, catalogs, it is flexible, beautiful and also reliable.

- Eyelets – metal rings for attaching banners. Installed with folds, with soldering or in one layer. Serve for greater reliability and durability of printing.

Most printing products require one or more of the above steps. Upon completion, decorative types of finishing can also be applied:

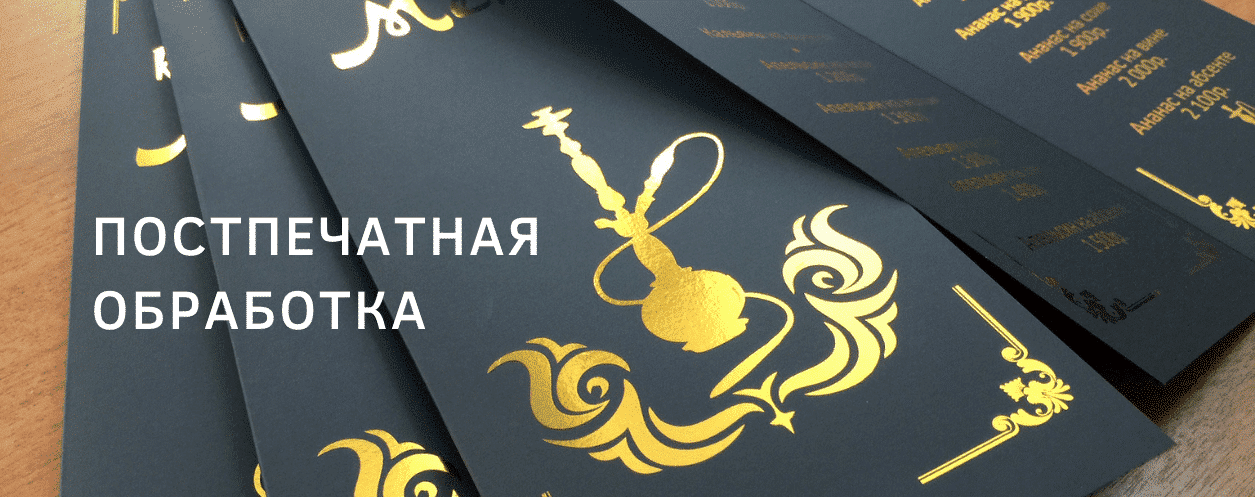

- Stamping, foiling – give products a more status, presentable, expensive look. They are made in the form of convex or concave impressions using a metallized layer. Relevant for postcards, invitations, business cards and other printing, where aesthetics is important.

- Lamination is a special coating that protects against moisture and mechanical damage. Laminated products look more effective and last longer. The film itself for work can be matte, glossy, have different densities. The most common are laminated magazines, catalogs, brochures.

- Perforation – creating tear lines on printed products using special perforating knives. Small holes are punched into the surface, allowing you to break the product without disturbing the neat, even edges. This service is relevant when printing tickets, tear-off calendars, stamps, notebooks.

- Rounding of corners – gives smoothed shapes to printing for external beauty and practicality. The corners are not wrinkled or damaged from careless use. It is used in the manufacture of calendars, stickers, discount cards, business cards.

Now you know what post-printing is, and you will be able to create the most beautiful and high-quality printing. And the first experimental printing house in Kharkov Exp-Print will help you with this at every stage.

What is post-printing and what is it for?

What is post-printing for?

When the products have already been printed and, in fact, are ready for use, it is the turn of post-printing. This is not an obligatory stage, but the finished appearance, durability, and attractiveness of the printing industry depend on it. Postprinting is conventionally divided into functional and decorative. Let’s take a closer look at each of the categories and the features of its manufacture.

Types of printed materials finishing

Most of the printing industry after printing requires the use of some kind of functional post-printing processing. It can be die-cutting or cutting, creasing, folding, stitching, binding, lacing. At the request of the client, decorative finishing can also be used – foiling, embossing, lamination, perforation, rounding of corners.

- Nibbling, cutting – the process of obtaining the required size of printing. Used to make small items such as postcards, business cards, invitations, etc. Cutting creates simple geometric shapes, and nibbling creates complex shapes.

- Creasing and folding – finishing required to create even and neat folds on booklets, packaging, calendars, folders. Creasing is relevant for products made of thick cardboard, paper, and folding is used for thin printed products.

- Binding – binding of printed pages in different ways – glue, spring, on staples. This is how books, magazines, booklets, catalogs, brochures and other multi-page publications are produced.

- Binding is the step after binding. Arranges individual bound pages into a single piece. It can be hard and soft. The first one is used for books, scientific papers, is more durable, reliable, practical. The second is inherent in magazines, catalogs, it is flexible, beautiful and also reliable.

- Eyelets – metal rings for attaching banners. Installed with folds, with soldering or in one layer. Serve for greater reliability and durability of printing.

Most printing products require one or more of the above steps. Upon completion, decorative types of finishing can also be applied:

- Stamping, foiling – give products a more status, presentable, expensive look. They are made in the form of convex or concave impressions using a metallized layer. Relevant for postcards, invitations, business cards and other printing, where aesthetics is important.

- Lamination is a special coating that protects against moisture and mechanical damage. Laminated products look more effective and last longer. The film itself for work can be matte, glossy, have different densities. The most common are laminated magazines, catalogs, brochures.

- Perforation – creating tear lines on printed products using special perforating knives. Small holes are punched into the surface, allowing you to break the product without disturbing the neat, even edges. This service is relevant when printing tickets, tear-off calendars, stamps, notebooks.

- Rounding of corners – gives smoothed shapes to printing for external beauty and practicality. The corners are not wrinkled or damaged from careless use. It is used in the manufacture of calendars, stickers, discount cards, business cards.

Now you know what post-printing is, and you will be able to create the most beautiful and high-quality printing. And the first experimental printing house in Kharkov Exp-Print will help you with this at every stage.

First Model

First Model